Was away from home for a bit, then came back to a very busy work week. Taking some "time off" from a project is often a good thing— it makes you appreciate hobby time even more.

Today, I had a chance to test all those painting experiments from a few weeks ago on the apron:

I'm pretty happy so far, but have a LOT more to paint.

August 2, 2015

July 10, 2015

Painting Experiments

Inspired an old online article, I decided to start experimenting with techniques for painting the top deck of the ferry dock.

Instead of using RIT dye, I decided to start with a thin wash of black acrylic paint (Vallejo Model Air Black) followed by dry brush successive coats of lighter colors (Dark Sea Grey and Deck Tan). Following another online hint, I used some yellow ochre pigment to try to warm up the deck as a final step:

I have a lot of decking to paint, so I'll probably continue experimenting with blending the PCB and plastic together in a believable fashion.

After last night's experiment, I used the remaining gray washes to create a high tide mark on the piling wall:

Instead of using RIT dye, I decided to start with a thin wash of black acrylic paint (Vallejo Model Air Black) followed by dry brush successive coats of lighter colors (Dark Sea Grey and Deck Tan). Following another online hint, I used some yellow ochre pigment to try to warm up the deck as a final step:

I have a lot of decking to paint, so I'll probably continue experimenting with blending the PCB and plastic together in a believable fashion.

After last night's experiment, I used the remaining gray washes to create a high tide mark on the piling wall:

June 29, 2015

Weekend Update

Had some time over the weekend to continue working on the ferry dock. With all the turnouts built, it was now time to focus on the "easy" track.

I've become quite fond of the FastTracks "plain old track" jig for making straight track— so it was time to try using it to make the straight section of the pier. I started by making a simple section, then adding my longer PCB ties to the newly constructed rigid track:

Removing the "standard" ties, I end up with what I want:

Once I had the decking in place, I cut some scribed styrene:

...and fit the pieces between the PCB ties.

As the night drew to a close, I stood up on the chair to check my work against a prototype photo. My dock is meant to go onto a module, so I'm purposely beefing up some of the framework underneath the deck. To my eyes, I'm pretty close:

June 16, 2015

Getting back to work

I finally got past some work deadlines and had a chance to build the "easy" turnout for the ferry slip. Started out with a Fast Tracks #7 turnout template, and a bit of graph paper trimmed to the contours of the dock.

Like the earlier 3-way turnout, I decided to use "extra-long" tie strips that could be blended into the decking. After a bit of filing and soldering, I spliced the new left hand switch onto the existing track work. I ended up cutting the ME code 40 rail joiners down to a more reasonable length, but I'm not 100% happy with their appearance.

After I was happy with the splice, I flipped the whole assembly upside down to solder additional bracing to the underside of the PCB ties:

After some tweaking, I now have all the turnouts in place on the dock:

P.S.: Yes, I know I still need to add the throwbar to the turnout. Next up, continuing the spur that runs down the left hand pier.

Like the earlier 3-way turnout, I decided to use "extra-long" tie strips that could be blended into the decking. After a bit of filing and soldering, I spliced the new left hand switch onto the existing track work. I ended up cutting the ME code 40 rail joiners down to a more reasonable length, but I'm not 100% happy with their appearance.

After I was happy with the splice, I flipped the whole assembly upside down to solder additional bracing to the underside of the PCB ties:

After some tweaking, I now have all the turnouts in place on the dock:

P.S.: Yes, I know I still need to add the throwbar to the turnout. Next up, continuing the spur that runs down the left hand pier.

April 27, 2015

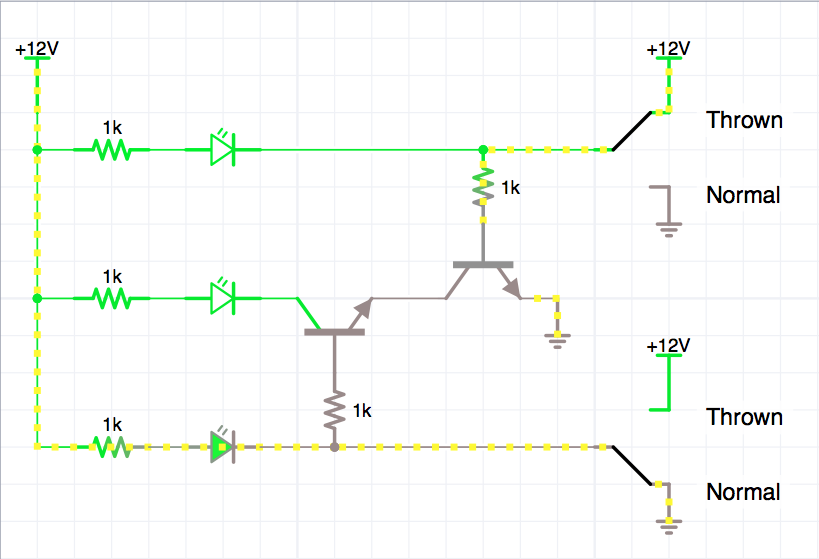

Crossover indication with DTL logic…

Over on TheRailWire, someone asked if it was possible to create a circuit for indicator LEDs to properly show the crossover route if an only if the turnouts were both aligned using only the half of the DPDT contacts on the turnouts. Here's a quick Diode-Transistor logic circuit which would use jelly bean NPN transistors (2N2222) to create a simple logic gate for the crossing route:

Both Turnouts "Normal"

One Turnout "Thrown"

Both Turnouts "Thrown"

March 18, 2015

Power routing fun

The 3-way switch has turned out to be a real head scratcher sometimes, but thankfully, I've realized a bunch of the power routing can be done with the existing DPDT contacts on a Tortoise motor.

Here is a look at the various turnout routes and how each section of rail should be powered:

The top "gauntlets" are powered just like a normal switched frog in a conventional turnout. It is just that the left and right turnouts are stacked atop each other. The center frog is powered from either the "left" or "right" routes; and dead otherwise.

Locking out the illegal route is all that is really left to do— and that can be either accomplished by clever software or hardware interlocking.

Here is a look at the various turnout routes and how each section of rail should be powered:

The top "gauntlets" are powered just like a normal switched frog in a conventional turnout. It is just that the left and right turnouts are stacked atop each other. The center frog is powered from either the "left" or "right" routes; and dead otherwise.

Locking out the illegal route is all that is really left to do— and that can be either accomplished by clever software or hardware interlocking.

March 8, 2015

Getting to the Point(s)

Worked on the 3-way turnout again today. Took a few iterations to tune the points as the constraints are a bit fiddly. Thankfully the opposite points help act as guardrails and pull the car down the correct path.

The points are "interesting" as they overlap and must be thrown in sequence to set the route:

February 7, 2015

Building the 3-way turnout

A productive modeler once told me: "Try to work on your railroad every day, even if it is only for a few minutes."

Taking that to heart, I decided to embark on the something I had been putting off for a few months: building the 3-way switch for the China Basin ferry dock.

I started with a set of paper FastTracks templates (http://www.handlaidtrack.com/Fast-Tracks-Printable-Track-Templates-s/11.htm), cut them up, and taped them together to get a reasonable looking three-way switch:

Using my Xuron flush cutters, files, and FastTracks PointForm/StockAid tools, I spent a few evenings cutting, filing, fitting, and soldering rails. I used Cloverhouse PCB tie strips (http://cloverhouse.com/Store/product_info.php?cPath=35_36&products_id=67) and MicroEngineering Code 40 Rail. I built from the middle rails to the outer rails, which is the opposite of my usual build order.

First Frogs (#12)

Center Route (Point rails)

Building the Righthand Route

During the build process, it is critically important to check the turnout dimensions using an NMRA Standards gage. A piece of Rolling stock and/or truck is also very helpful.

After a few nights, I managed to get the rest of the rails in place:

At this point, you are probably saying, "Why the 3#@k is he using such long PCB ties?" Well, they say that a picture is often worth 1,000 words, so here you go:

Next steps will be to get that nested set of points to throw properly... more on that soon.

January 5, 2015

Building the Pilings

The next phase of the ferry dock was building the piling walls along the inside edges of the dock.

In a departure from the plastic construction I had been using to build the trestle sections, I decided to try my hand with using real wood to represent wood.

First, I stained 3/16" hardwood dowels using thinned Vallejo Model Color 70-822 German Black Brown:

After cutting an insane number of pilings, I got out some "dark wood" carpenter's glue (it dries brown instead of yellow) and started to assemble the wall. Working from photos, I realized that the pilings needed to be spaced apart AND an extra layer of angled timbers were used to tie the wall together:

I really liked the look of the wood, but then I realized the next phase of the problem— I needed to paint the white plastic trestle sections.

As a test, I took the thin section of the dock, and painted it with Games Workshop Chaos Black primer, then began dry brushing Vallejo paints over the black. I ended up dry brushing over the primed dock with the 70-822 German Black-Brown and 70-871 Leather Brown.

Here's a better look at the progress so far (with the barge for a reference):

Subscribe to:

Comments (Atom)